Flatness Measurement: Diagonal Method

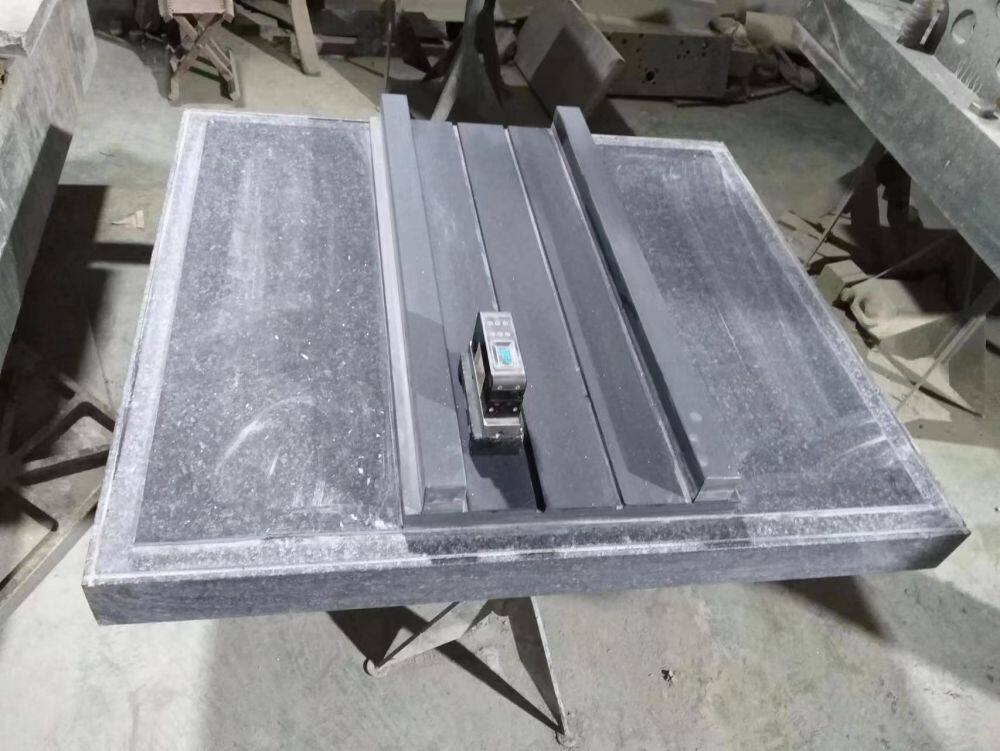

Flatness measurement of marble platform using the diagonal methodElectronic level diagonal method: Unlocking new horizons in the flatness measurement of granite precision platforms

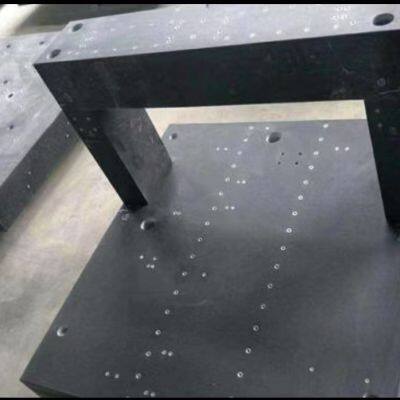

I. Preparations before measurement: All set, just need to measureFirstly, we need to ensure the stability of the measurement environment. Place the granite precision platform in a place with relatively stable temperature and humidity, and no vibration interference, to avoid factors affecting the measurement results. Next, prepare a high-precision electronic level. Compared with traditional levels, electronic levels have the advantages of high precision, easy data reading, and the to connect to computers for data analysis. Before use, the electronic level should be calibrated to ensure it is in the best working condition. At the same time, prepare a table electronic document to record the measurement data, which is convenient for subsequent data organization and analysis.

II. Principle of diagonal method measurement: The wisdom of simplifying complexity

The principle of the diagonal method to measure flatness is to measure the straightness error on two diagonals and several lines parallel to the diagonals of the granite precision platform, then evaluate the flatness of the entire plane. Simply put, it is to convert the complex flatness measurement into the measurement of multiple straight lines, which is both scientific and efficient

III. Specific measurement steps: Step by step, precise control

1. Determine the measurement points: On the granite precision platform, mark out two diagonals (such as the top left corner to the bottom right corner, from the top right corner to the bottom left corner), and divide the diagonals into several equal segments. Generally, it appropriate to divide into 5-10 segments according to the size and accuracy requirements of the platform. These equal points are our measurement points, and at the same time, several parallel to the diagonal are also selected, and the measurement points are marked.

2. Start measuring: Place the electronic level on the starting measurement point, level it, and then and record the data. Then move the electronic level along the diagonal or the cut line one by one, each moving one measurement interval, ensuring that the level is tightly attached to platform, avoiding any tilt or shake, and reading and recording the data at each measurement point. During the measurement process, attention should be paid to maintaining the continuity and consistency of the to prevent data deviation.

3. Data processing: After the measurement is completed, we get a series of data. Use the least squares method or other suitable methods to process these. Through professional data analysis software, the flatness error value of the granite precision platform can be calculated quickly and accurately. If there is no professional software, it can also be calculated, but it needs to be more careful to avoid calculation errors.

4. Result judgment: Compare the calculated flatness error value with the flatness tolerance requirements of the granite precision. If the error value is within the tolerance range, it indicates that the flatness of the platform meets the standard and can be used normally; if the error value exceeds the tolerance, the platform needs to be repaired or reprocessed until it meets the requirements.

Recently Posted

-

Precision Granite Surface Plates & Bases Product Specification Catalog

January 5, 20261. Introduction & FeaturesShandong JinteLai Precision Machinery Co., Ltd specializes in manufacturing high Read More

Read More -

Core application areas of granite precision mechanical components

December 9, 2025Core application areas of granite precision mechanical components 1. Semiconductor and integrated circuit manufacturing · Pho Read More

Read More -

Shandong Jintale Precision Machinery Co., Ltd.

December 3, 2025Shandong Jintai Lai Precision Machinery Co., Ltd. is a comprehensive stone enterprise integrating research and development, produc Read More

Read More