Precision Granite Surface Plates & Bases Product Specification Catalog

1. Introduction & Features

Shandong JinteLai Precision Machinery Co., Ltd specializes in manufacturing high-precision granite surface plates, bases, and machine components from selected natural granite. Our products are the benchmark for stability, accuracy, and longevity in precision measurement, quality control, and advanced manufacturing.

The company has constant temperature processing and inspection conditions, and is equipped with advanced precision electronic inspection instruments, and the production inspection process and product packaging meet the international export standards The company has always adhered to the principle of integrity and quality first, and is committed to meeting customer needs with advanced technology and scientific management, providing customers with reliable quality assurance,-oriented, with first-class quality, reasonable price and the shortest cycle, to provide high-quality products and all-round services for customers.

Core Advantages:

· Ultra-Stable: Negligible thermal expansion, stress-relieved, maintains flatness for decades.

· Superior Accuracy: Can be calibrated to meet or exceed international Grade 00 standards.

·Extremely Durable: High hardness (Mohs ≥6.5), wear-resistant, corrosion-proof, and non-magnetic.

· Low Maintenance: No rust, no need for protective coating. Easy to clean.

· Cost-Effective: A "once-in-a-lifetime" investment due to its unparalleled durability.

2. Standard Product Line & Specifications

2.1 Granite Surface Plates 【Standard Sizes (Unit: mm)】

Marble flat plate specifications, weight and precision

Specifications Length×Width×Height | Weight kg | 000 grade accuracy μm | 00 grade accuracy μm | 0 grade accuracy μm | 1 grade accuracy μm |

300×300×50 | 19 | 1.5 | 3 | 6 | 12 |

400×300×70 | 25 | 1.5 | 3 | 6 | 12 |

400×400×70 | 48 | 2 | 3.5 | 6.5 | 13 |

630×400×100 | 76 | 2 | 3.5 | 7 | 14 |

630×630×100 | 155 | 2 | 4 | 8 | 16 |

800×600×100 | 156 | 2 | 4 | 8 | 16 |

1000×630×130 | 284 | 2.5 | 4.5 | 9 | 18 |

1000×750×150 | 338 | 2.5 | 5 | 9 | 18 |

1000×1000×150 | 450 | 2.5 | 5 | 10 | 20 |

1600×100×0200 | 963 | 3 | 6 | 12 | 24 |

2000×1000×200 | 1200 | 3.5 | 6.5 | 13 | 26 |

1600×1600×300 | 2312 | 3.5 | 6.5 | 13 | 26 |

2000×1600×300 | 2890 | 3.5 | 7 | 14 | 28 |

2500×1600×300 | 3612 | 4 | 8 | 16 | 32 |

3000×2000×500 | 9030 | 4.5 | 9 | 18 | 36 |

4000×2000×500 | 12040 | 5.5 | 11 | 22 | 44 |

6000×2000×700 | 25284 | 7.5 | 15 | 30 | 60 |

Note: Other sizes and special thicknesses can be custom made.

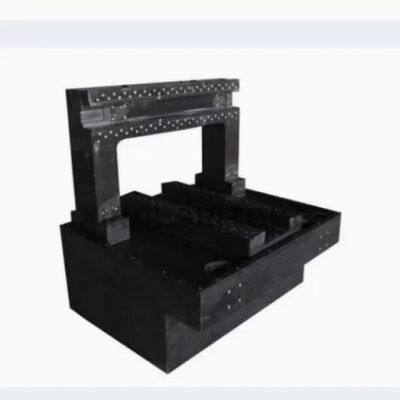

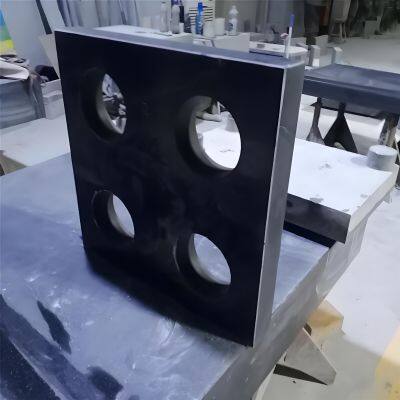

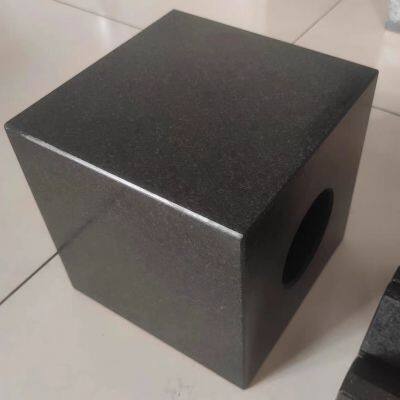

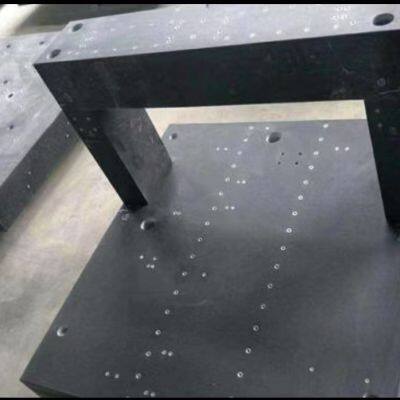

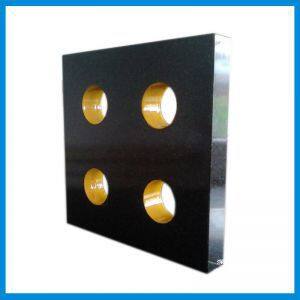

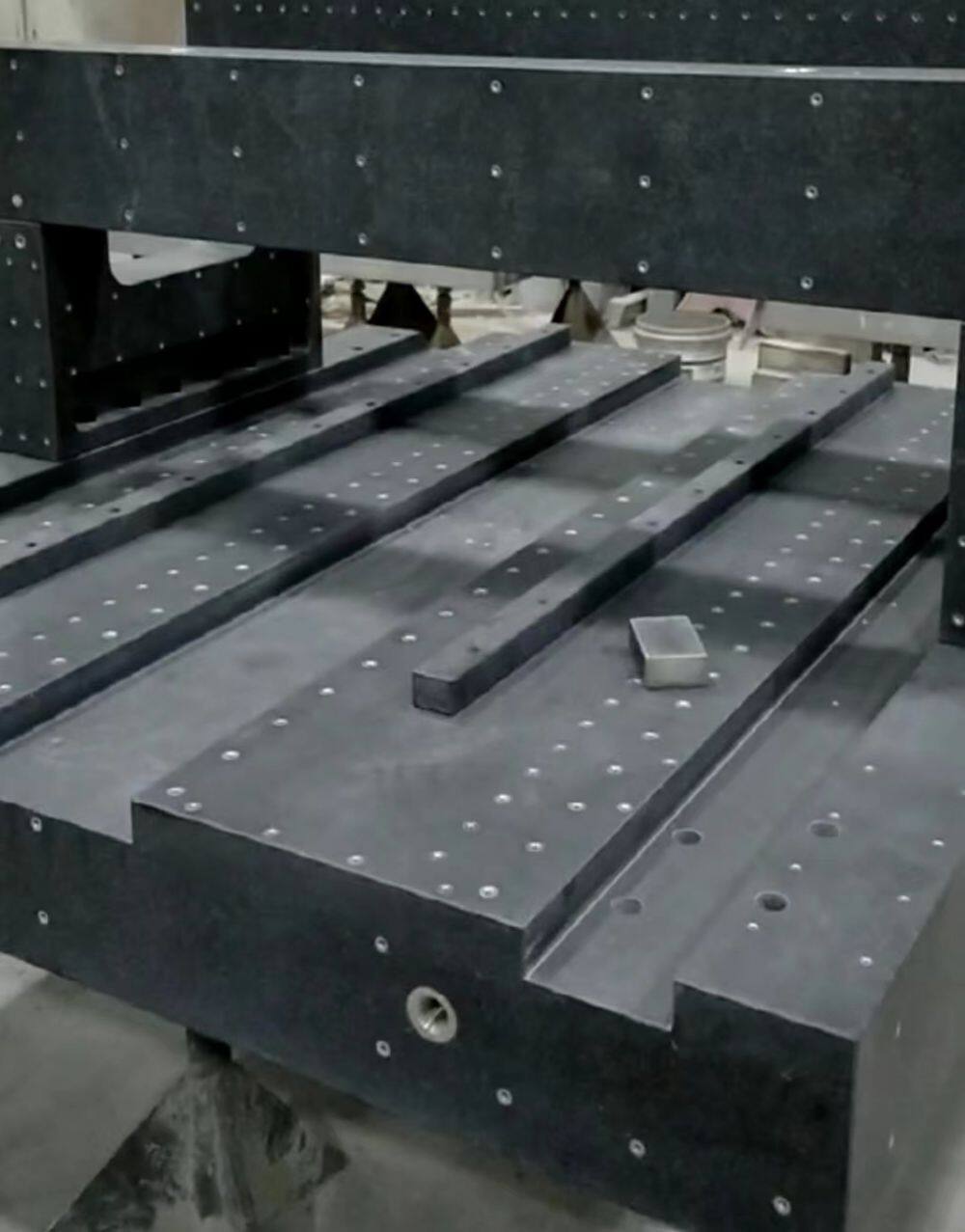

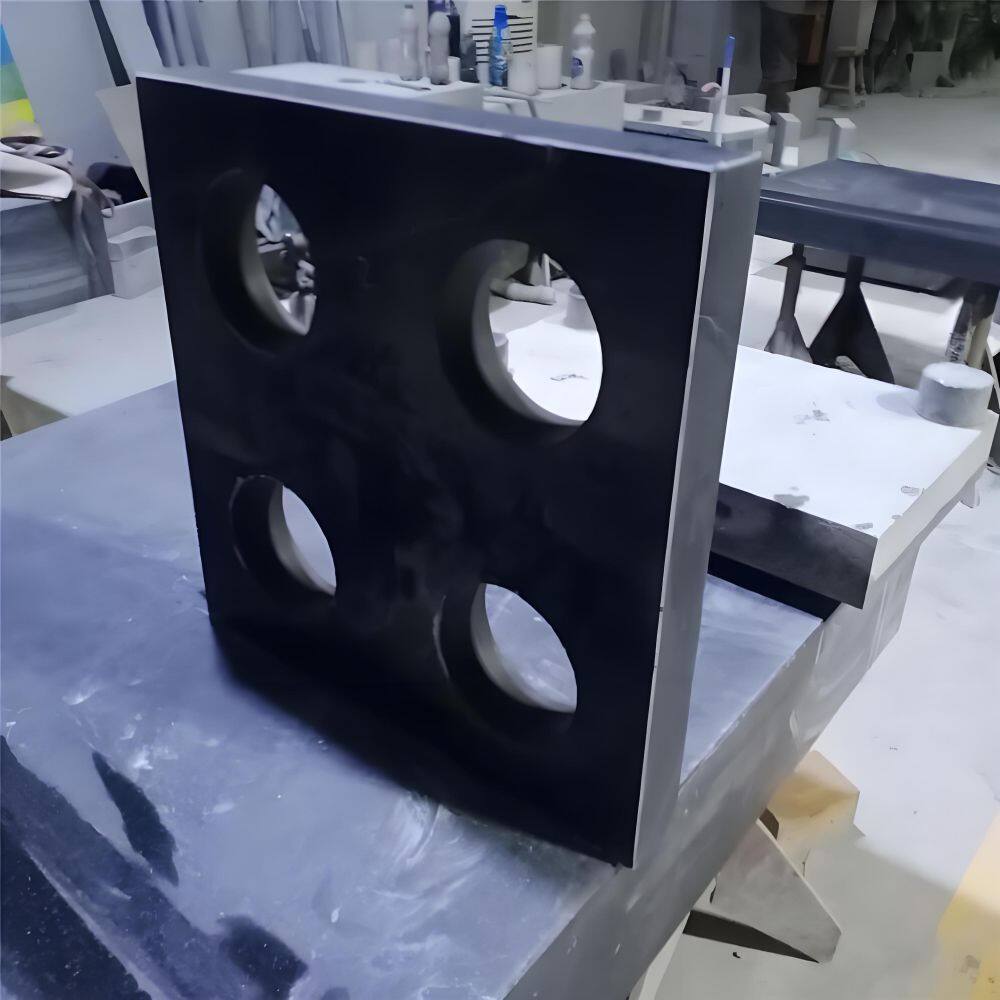

2.2 Granite Machine Components(Customization Services)

Custom Dimensions: Any size and thickness available.

Special Machining: Through-holes, threaded inserts, recesses, step features, special grooves.

Granite Base / Bed Rigid base for CMM, vision systems, and sensitive equipment. Fully customizable (L, W, H, holes, recesses).

3.Technical Data & Standards

The precision of granite slab shall refer to the advanced national standards, and the flatness tolerance shall be in accordance with JB/T7975-1999 standard: Class 000=1 × (1+d/1000) um level 00=2 × (1+d/1000) um Level 0=4 × (1+d/1000) um Level 1=8 × (1+d/1000) um (d is diagonal mm) (measurement temperature is generally 20 ± 2 ℃

4. Quality & service

Quality control 100% flatness test before shipment;

Warranty 12 months warranty against manufacturing defects (Not including abuse and man-made damage)

If any problem occurs with the product during use, we will provide remote guidance via phone or other communication tools, in addition, we will also provide experience daily maintenance and care of the product.

5. Packing & Delivery

Standard Packaging: Protected corners, plastic wrapping, enclosed in a robust wooden export crate.

Lead Time:

Standard sizes: 15-25 working days after order confirmation.

Customized products: 25-40 working days, depending on complexity.

Shipping:Shanghai / Tianjin / Qingdao / or as per customer request.

6. How to Order or Request a Quote

To receive a precise quotation and lead time, please provide the following information:

1). Product specifications or Detailed Dimensions (Length, Width, Height).

2). Required Accuracy Grade (Grade 00, 0, etc.).

3). Quantity.

4). Special Requirements (T-slots, holes, inserts, etc.).

5). Destination Port / Country.

Contact Us for Engineering Consultation or Custom Design.

Recently Posted

-

Core application areas of granite precision mechanical components

December 9, 2025Core application areas of granite precision mechanical components 1. Semiconductor and integrated circuit manufacturing · Pho Read More

Read More -

Flatness Measurement: Diagonal Method

December 6, 2025Flatness measurement of marble platform using the diagonal methodElectronic level diagonal method: Unlocking new horizons in the f Read More

Read More -

Shandong Jintale Precision Machinery Co., Ltd.

December 3, 2025Shandong Jintai Lai Precision Machinery Co., Ltd. is a comprehensive stone enterprise integrating research and development, produc Read More

Read More