The treatment method for the precision deviation and stability decrease of the granite surface plate

Step 1: Comprehensive Diagnosis and Root Cause Analysis (Find the "Root Cause" before Prescribing the "Rem")

Firstly, it is imperative to cease operation on the high-precision workbench and conduct a systematic inspection.

1. Environmental Factors Check (The common yet easily overlooked reasons):

· Temperature Field Mapping: Use an infrared thermometer or temperature sensor to inspect the temperature distribution on the surface, bottom, and surrounding environment the workbench. Are there any instances of direct sunlight, air conditioning/heater vents blowing directly, nearby equipment heat sources, or excessive diurnal temperature differences? The environment is constant temperature (e.g., 20 ± 1℃), no gradients, no sudden changes.

· Vibration Test: Check if the is stable. Feel with your hand or a simple vibration meter, or observe whether the water surface in a cup placed on the workbench fluctuates. Are there any nearby vibration such as stamping machines, cranes, or heavy vehicles passing by?

· Humidity Check: Prolonged high humidity may affect the microstructure of the stone (although, it needs to be ruled out).

2. Inspection of the Workbench Itself and Its Installation:

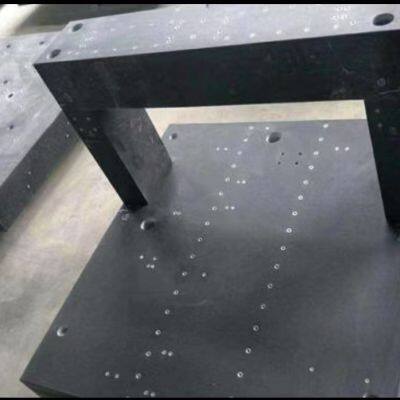

· Support System Review: Check if the support (typically three points or Bessel/Airy points) are secure and evenly loaded. Are the support pads or anchor bolts loose? Incorrect support is the primary cause of selfweight deformation.

· Levelness Check: Use a high-precision electronic level to check if the overall levelness of the workbench has changed.

· Visual and Tactileion: Carefully inspect the surface for any new bumps, scratches, cracks, especially in critical measurement areas and edges.

3. Review of Usage History:

· Record: Has there been any overloading? Were there concentrated loads or eccentric loads?

· Operation Record: Were there any violations of operation (such as striking, dragging work)?

Step 2: Take corresponding measures according to the diagnosis results

Case A: Caused by environmental or factors (precision may partially recover)

· Measures:

1. Eliminate the source of interference: Move away heat sources, add air conditioning baffles, building insulation, set up isolation grooves or active isolation platforms.

2. Fully temperature-stable: Let the platform rest in a standard temperature-stable environment for at least24-48 hours to make its overall temperature uniform and stable.

3. Re-measure precision: After temperature stability, re-detect with autocollim, electronic level, or laser interferometer.

· Result judgment: If the precision recovers or approaches the original value, it indicates that the problem is caused by environmental-induced elastic. It is necessary to improve the environment permanently and use it in a standardized way.

Case B: Caused by improper support or stress release (precision loss is permanent, intervention is required)

· Measures:

1. Professional re-leveling and support: Hire experienced engineers, use torque wrenches, and re-level according to the platform's own weight and the designed support points. It may be necessary to adjust the position of the support points or add auxiliary support (to be carefully calculated)

2. On-site grinding repair (suitable for moderate misalignment):

· To be operated by professional metrology/repair team.

· Use granite grinding machines (equipped with diamond grinding discs) for grinding on the original site of the platform.

· Advantages: No need to move, avoid secondary damage, can restore high precision (usually can reach the original precision grade or slightly lower).

· Disadvantages: It will produce dust, need to do a good job of; will reduce the thickness of the platform (micron level).

3. Return to the factory for overhaul (suitable for serious misalignment, deformation, or damage): · Transport the platform back to the manufacturer or a large repair center.

· The process includes: thorough stress release (may re-age harden) → precise grinding a large gantry CNC grinder → comprehensive inspection → issue a new calibration report.

· Advantages: It can fundamentally solve the problem, restore it to a new, or even upgrade the precision.

· Disadvantages: High cost, long cycle, and high transport risk.

Case C: Caused by local damage ( as dents, scratches)

· Measures:

· Small-scale filling: For small pits, special granite epoxy resin repair agents can be used for filling grinding, and polishing. But this is mainly used for anti-corrosion and aesthetics, and cannot restore the original precision of the point, which should be marked as " using area".

· Local grinding: For shallow groups of scratches, local manual grinding can be performed, but the impact on the overall flatness needs to be evaluated.

Step 3: Post-repair Calibration and Long-term Prevention

1. Authoritative Calibration: Regardless of the method used, a comprehensive calibration must be performed by a qualified third-party metrology institute or the original manufacturer using high-precision instruments (such as laser plane interferometers), a new calibration certificate should be issued as the new "precision ID" for the platform.

2. Establishing a Preventive Maintenance System:

· Regular Inspect: Develop a schedule (e.g., every quarter or every six months) for quick inspections using simple tools (e.g., straightedge, level).

· Periodic Calibration: Establish a formal recalibration cycle (usually 6 months, 1 year, or 2 years) based on usage frequency and precision, and strictly adhere to it.

· Environmental Monitoring: Install a temperature and humidity logger near the platform to continuously monitor environmental conditions.

· Operator Training: Re- all operators to emphasize proper operation and daily maintenance (e.g., cleaning immediately after use, covering with protective caps).

Recently Posted

-

Daily maintenance and care of the granite surface plate

January 14, 2026FAQ:Daily maintenance and care of the granite surface plateHow to Self-Repair and Maintain Scratches or Small Pits on the &nb Read More

Read More -

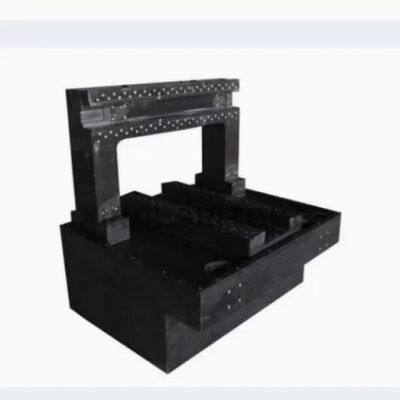

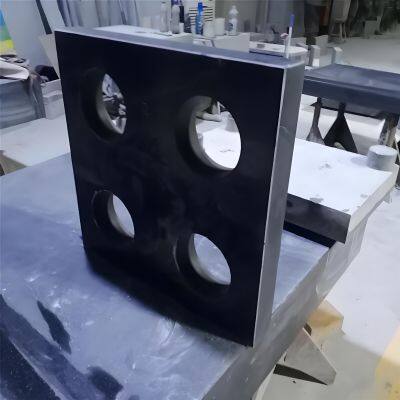

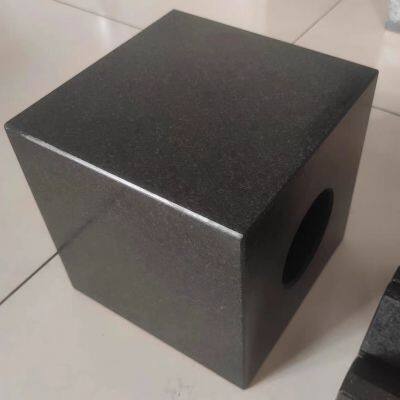

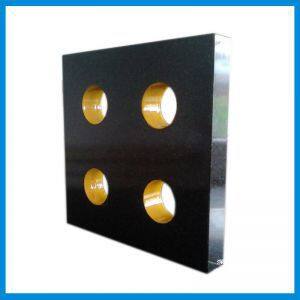

Precision Granite Surface Plates & Bases Product Specification Catalog

January 5, 20261. Introduction & FeaturesShandong JinteLai Precision Machinery Co., Ltd specializes in manufacturing high Read More

Read More -

Core application areas of granite precision mechanical components

December 9, 2025Core application areas of granite precision mechanical components 1. Semiconductor and integrated circuit manufacturing · Pho Read More

Read More -

Flatness Measurement: Diagonal Method

December 6, 2025Flatness measurement of marble platform using the diagonal methodElectronic level diagonal method: Unlocking new horizons in the f Read More

Read More